The Copper Cricket was, and still is, a simple, efficient and reliable solar water heating system. Most of those I visit these days are systems on homes in the process of being re-roofed. I help remove the collector and return to replace and recharge it. Once in a while a Cricket is out of sorts. The most I have had to do is flush the heat exchanger, replace the fuse plug and recharge it.

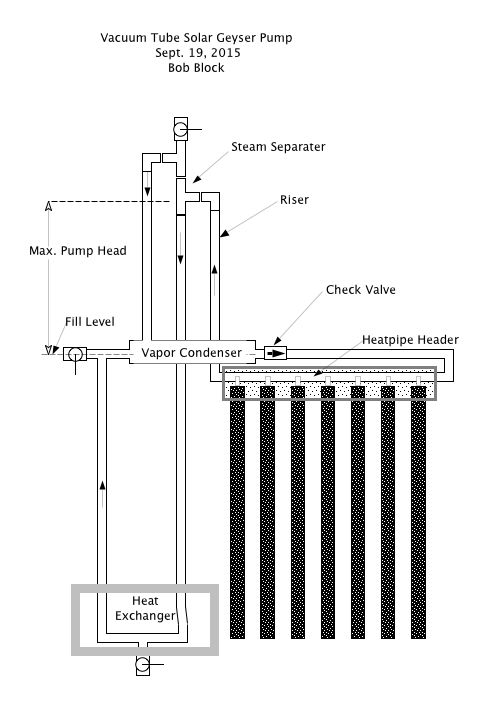

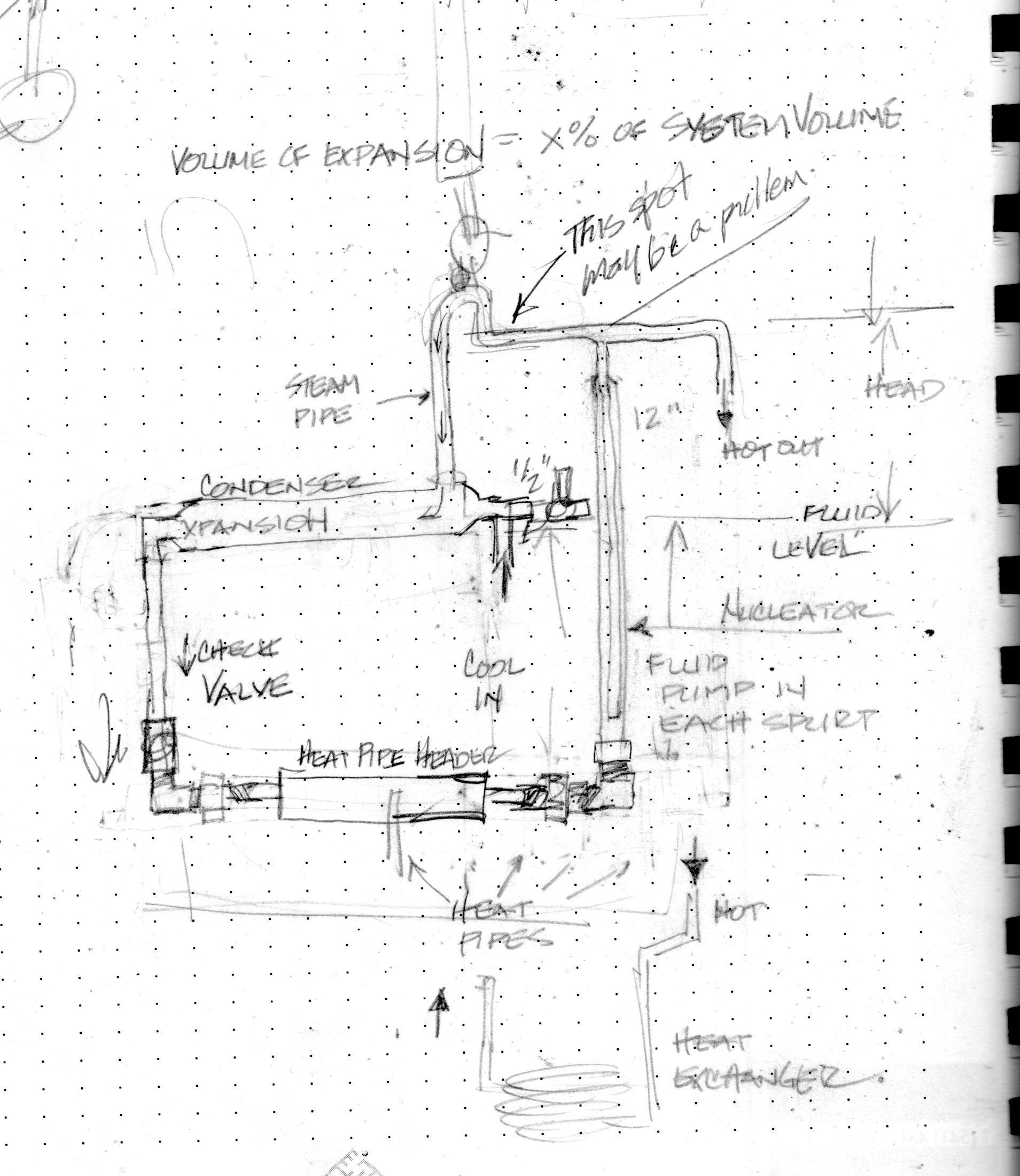

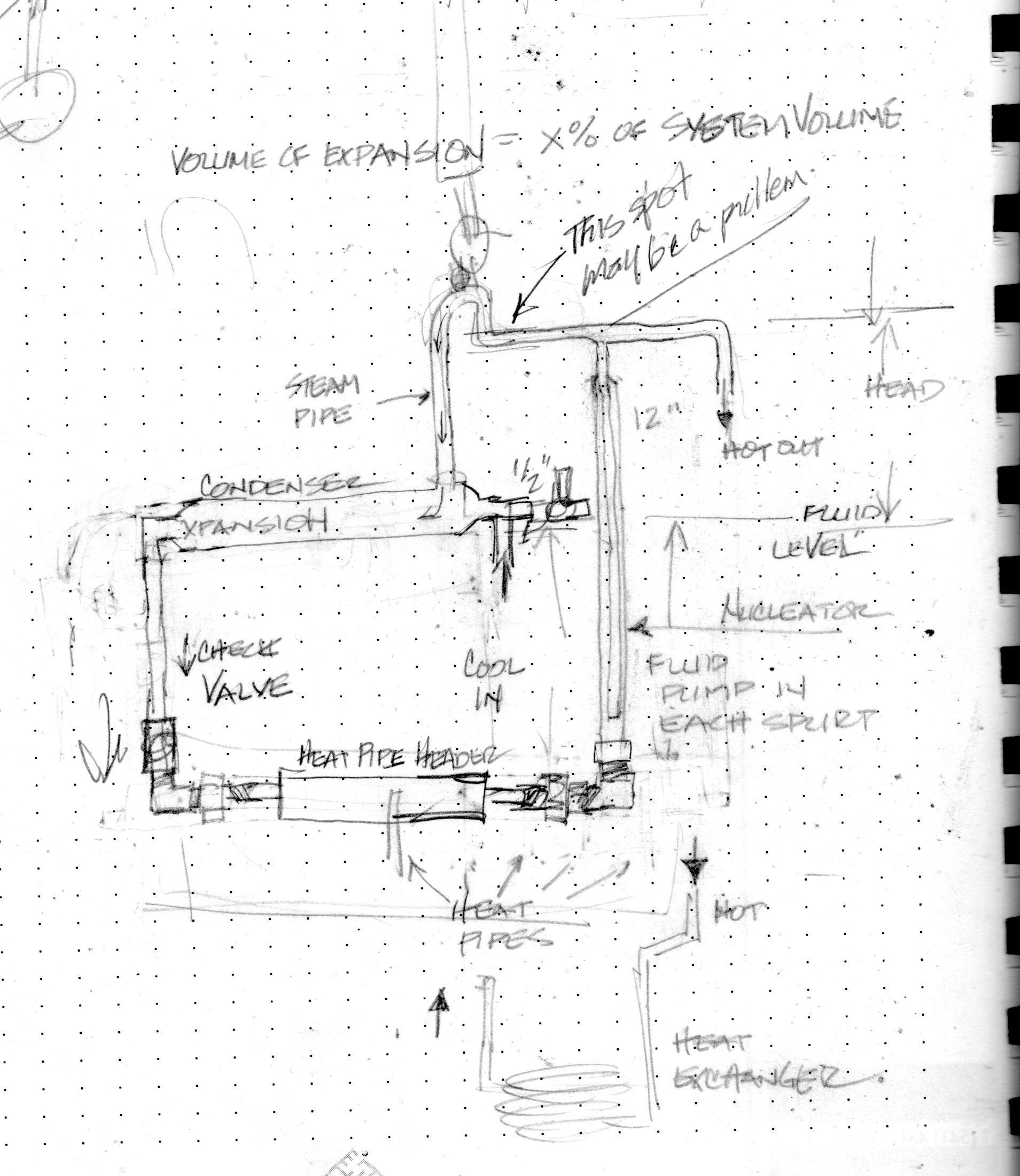

I had been considering integrating the Copper Cricket pump (geyser pump) with evacuated tube solar collectors. I envisioned several ways of doing this, but had not built one. In 2014 Raymond Lam of Silk Road Environmental contacted me because one of his clients had a non-functioning Copper Cricket, and he didn’t know what to do with it. I met him at the Cricket’s home in Portland and recharged the system. It had over heated while the home-owners were away on an extended summer vacation. Ray was excited about the system and spent the next several months trying to build a working model using the evacuated tubes and headers that he imports from China. After hitting a wall in development he hired me to troubleshoot his prototype. I visited him at his shop and determined pretty quickly that his prototype had no chance of working. He didn’t quite understand the functioning of the system. Instead of trying to get his to work, I showed him a sketch from my notebook. I said I thought this would work, but I hadn’t tried it yet.

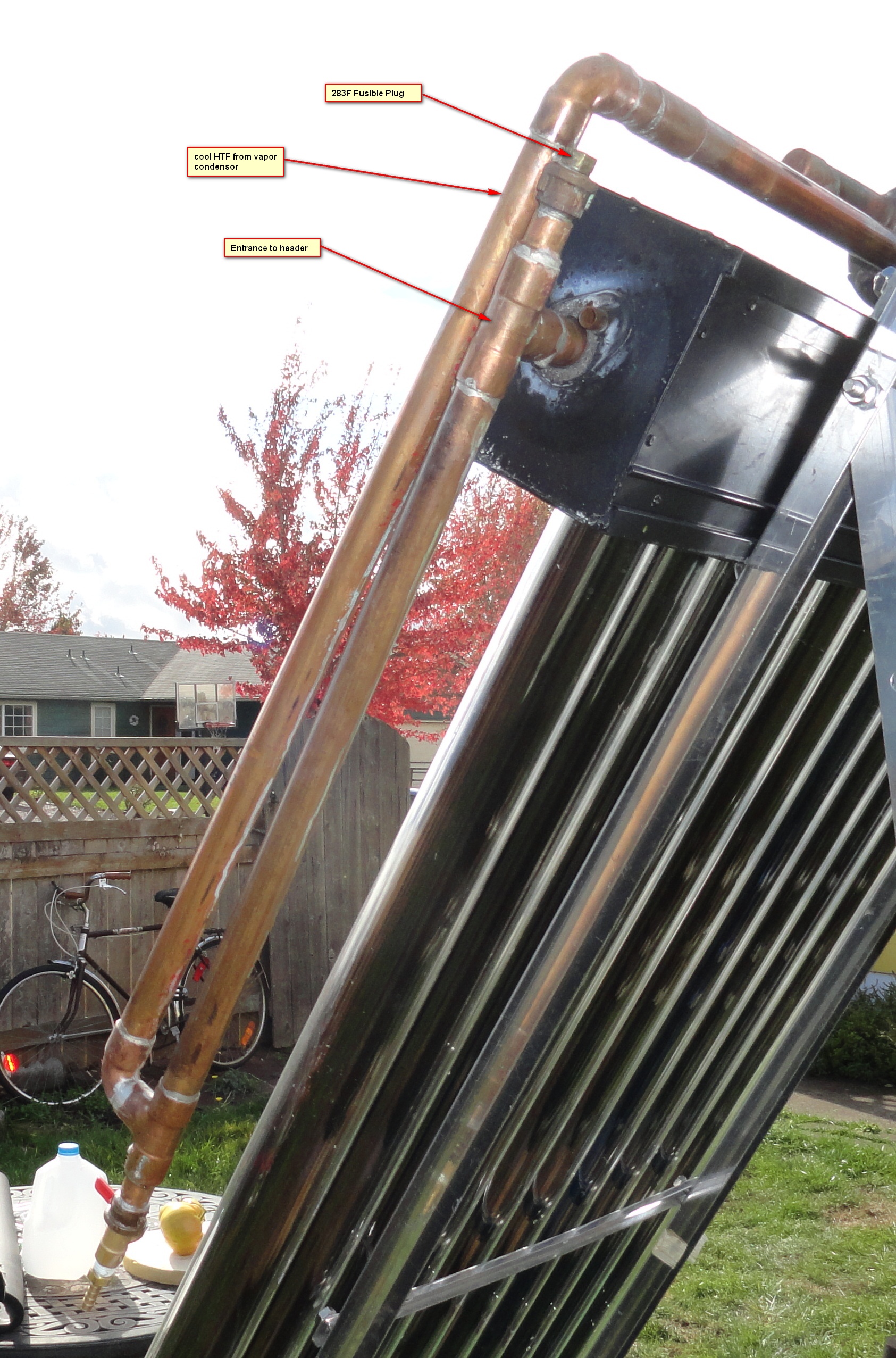

We rummaged through the fittings and fixtures in his warehouse and then went to the plumbing store to buy the rest of what we needed. We started to assemble the prototype that afternoon. I have to say, I was amazed at how quickly and easy it was to assemble his 20 tube evacuated tube collector.

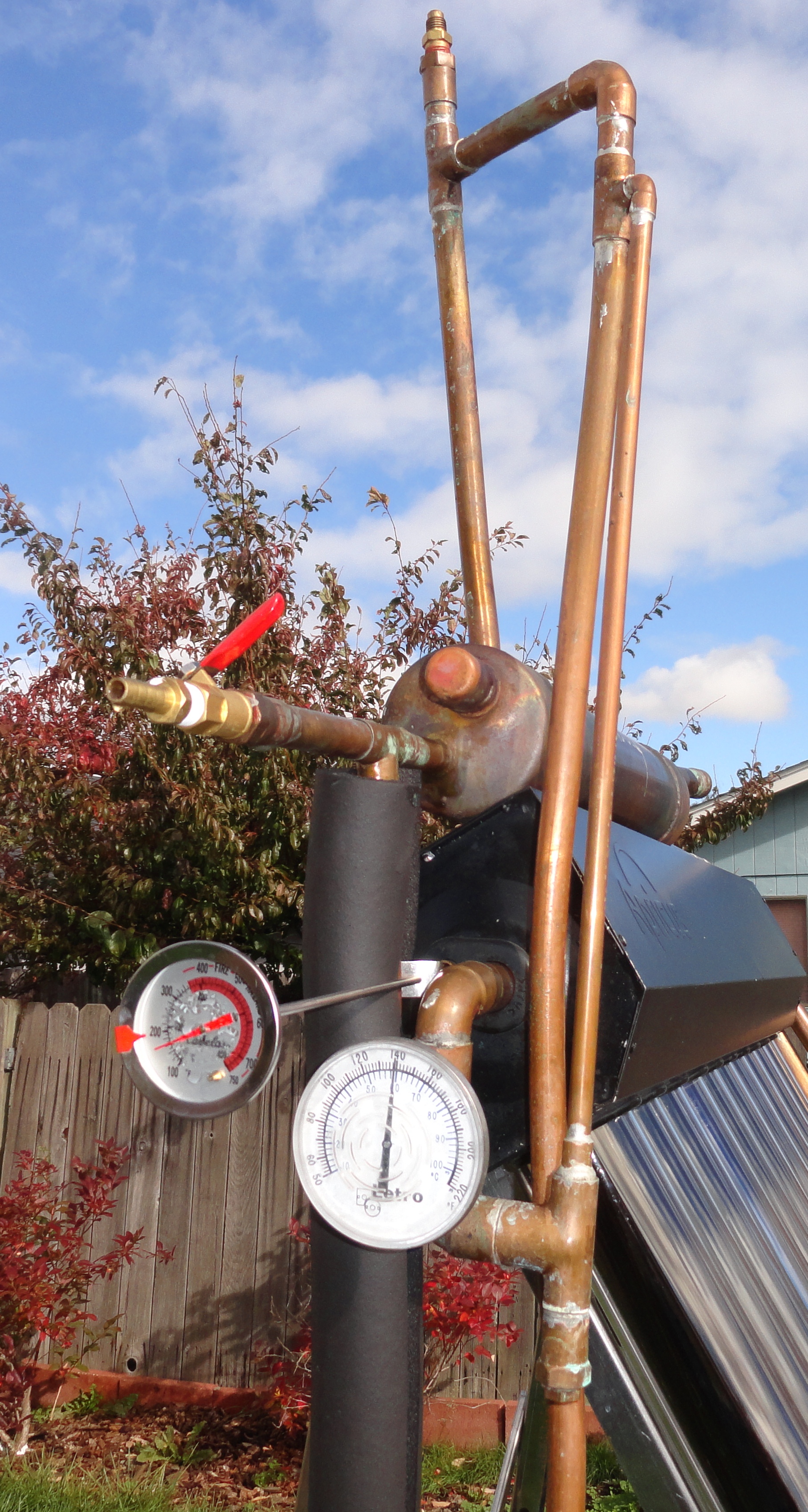

That night in my hotel I sketched the details of the prototype we would complete the next day. By 1pm we had completed the fabrication of the system and filled it with water. It pumped immediately, and I was able to track the rapid flow of heat through the uninsulated system. I suspected that the system would not hold a vacuum due to some of the odd fittings we had to use, so we let it run with the evacuation port open to the atmosphere. I didn’t try to measure the pump rate, but it was clearly fast enough to move fluid through the system, and very little steam was escaping the evacuation port which indicated that the steam was condensing internally.

Ray has decided to move forward with a proprietary revision of the system, so I agreed not to post photos of the one we built at his site, but I told him I was I would continue to move forward on my own and publish the geyser pump solar water heater as an open source technology.