Yesterday I had the pleasure to talk to Matt Carlson and Arnoud Van Houten of Sunnovations. Matt’s the business guy, and Arnoud is the inventor/technical guy. Their web site is www.sunnovations.com.

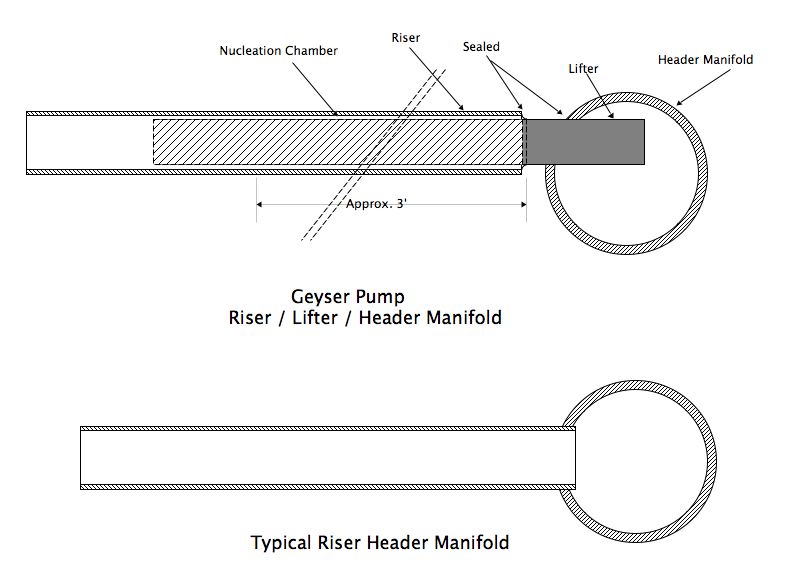

I found their web site when I was scouring the web for references to the Copper Cricket. At first glance I thought, “these guys have stolen our technology.” Then, after a bit of thinking, I realized we hadn’t done anything with it for 15 years, the patents have expired, and this is actually what I wanted to see happen: I wanted someone to use the technology. Of course my next step was to see if they had patents. They did. I downloaded their patent describing their version of the geyser pump and studied it carefully. I was pleased to see that not only did the patent refer to our patents, but also to a trade article about our product. The drawings looked like our early prototypes with some minor additions, but after reading further, those little additions were huge. I was very impressed by the improvements they made. Their product is easier to install and will re-create its own vacuum. It doesn’t require a vacuum pump to create an initial vacuum; it uses non-toxic propylene glycol as the antifreeze, and can be installed with plastic tubing. It has novel over-heat protection that dumps the fluid out of the collection plate before reaching 180F. They use standard flat-plate collectors, and don’t worry about nucleation.

We talked for about an hour and a half, mostly Van Houten and I exchanging ideas about the technology, and Carlson talking about their distribution channels. We also talked about how the Internet has changed the game. Remember, in 1995, the year Sage Advance went out of business, the Web wasn’t even public.

When I compare the two systems, I think the Copper Cricket still has a few advantages. I believe they will find that the CC is more efficient when compared with their SRCC certification which is currently under testing. I think the CC’s pump rate is faster than Sunnovation’s. In the long term, I think the CC will have a longer life-expectancy if a side-arm heat-exchanger is used. I have anecdotal proof that the CC with a side-arm heat-exchanger can remain in perfect operation for over 20 years with out maintenance.

When we discussed nucleation and boiling, Van Houten described the three types of boiling that they have seen: 1) fizzy boiling, where the fluid is full of bubbles as it is ejected from the lifter. This is what we saw when our early geyser pumps were starting up for the first time. It’s similar to when a pot of water is boiling. At first you see almost a complete coverage of the bottom of the pan with tiny bubbles. This type of boiling doesn’t pump fluid very effectively. 2) continuous slug pumping, where large slugs of hot fluid are ejected from the lifters. This is the optimum. I expect this is boiling that occurs at a few large nucleation sites along the tube a foot or so below the fluid level. A single bubble expands rapidly and drive hot fluid out of the lifter. 3) explosive boiling – we saw this type of boiling when we weren’t using nucleation tubes. When the early prototypes without nucleation ran for a week or so, the risers got really hot over 220F before they would discharge. When they did, they exploded with so much force that it rocked the collector stand. It is why we installed the evil check-valve in the faller (the pipe from the vapor condenser outlet to the footer manifold.) After adding the nucleating risers, we were able to remove the check valve.

I look forward to seeing the Sunnovations SRCC rating. I think the Sunnovations product has potential to service the demand in the single-family dwelling market segment. It should be mandatory that single family dwellings install solar water heaters before they are eligible for publicly funded incentives for photo-voltaic systems. Solar water heaters are 5 times more efficient that PVs,