Lance Dyer first contacted me in August. I stopped in to see his Cricket while returning home from a camping trip in Bend. His Cricket had stagnated because the house had been in foreclosure for over a year. The house plumbing had been ‘winterized’ leaving no water in the solar tank. When they took possession of the home, in the Spring of 2012, the Cricket was not working. Lance called around to local solar companies and they recommended swapping out the 20 year old system for a new one. He found my Web site and connected me the day before I was leaving to camp within 5 miles of his home.

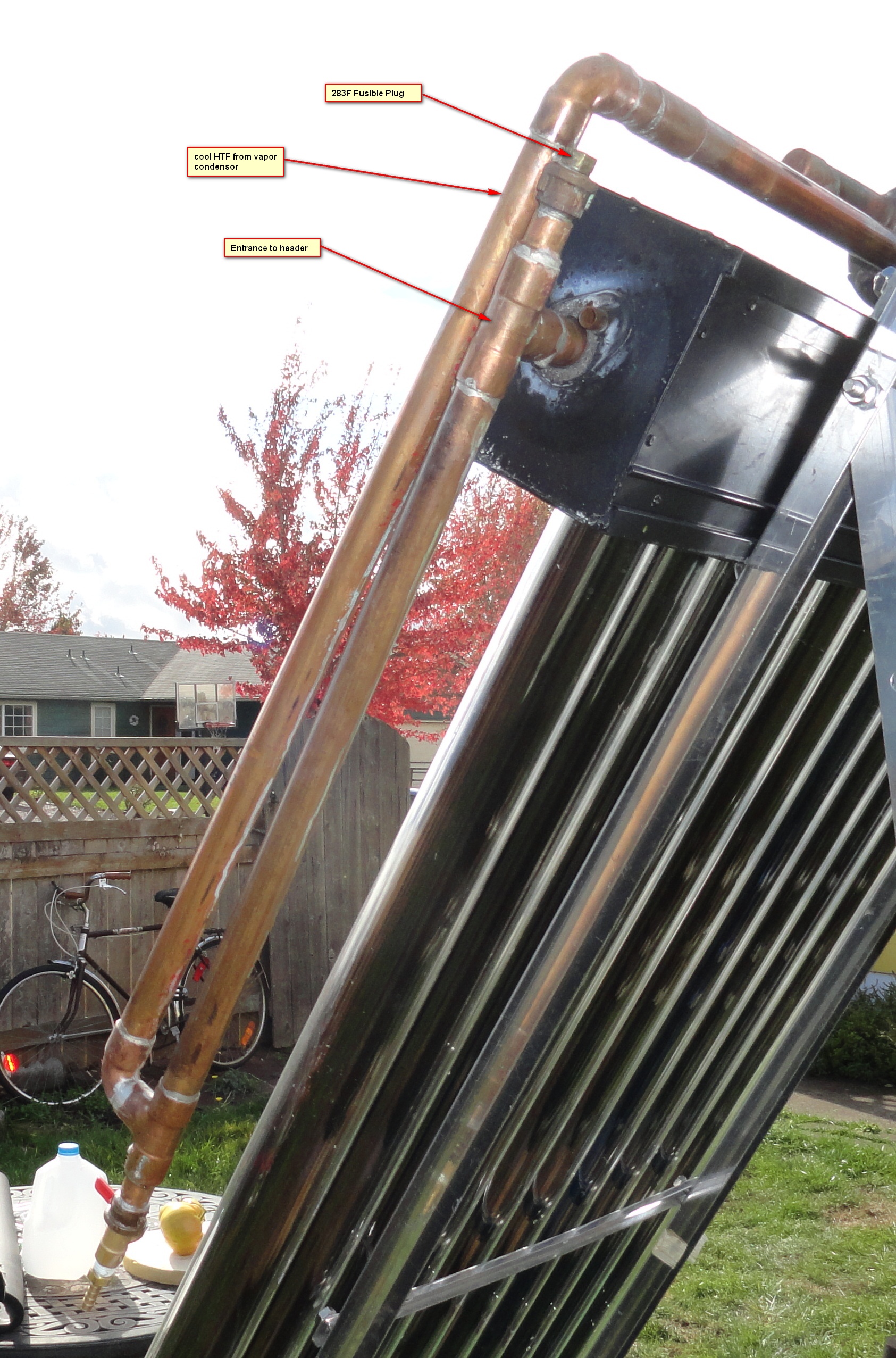

Upon my arrival he already had the ladder in place. It is a first story installation only a few yards horizontally from the storage tank. A standard two-tank system with two 50 gallon electric water heaters. The fuse plug had blown, but no other damage was apparent. I told him I would return with a charging kit. My charge was lodging plus $170. The Dyers also fed us lunch, dinner and beers while we watched the Ducks play. All in all it was a very pleasant vacation.

They lodged us (Elizabeth came with) in a nice Best Wester motel in Sisters.

We arrived Saturday at about 12. Here’s what we did.

- Install fuse plug with RTV

- Install drain valve – I didn’t remember that the second generation Crickets used ¼” drain valves. Luckily I had brought a bag full of spare parts and used many of them throughout the day.

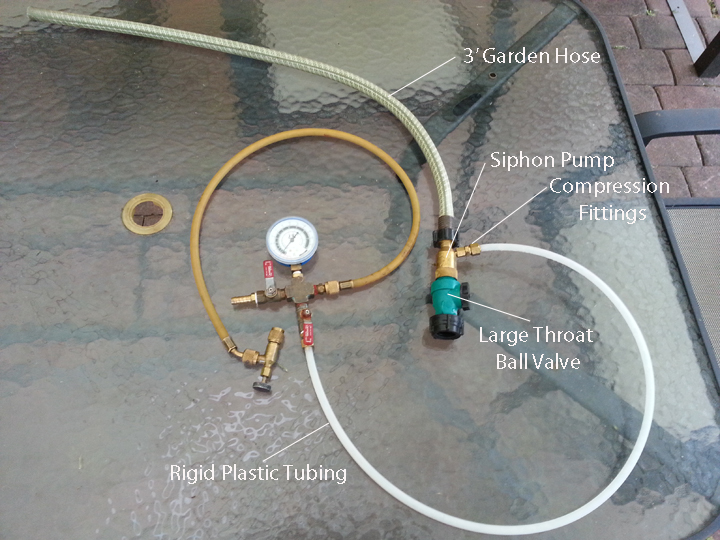

- Pressurize system to 110PSI. I needed a yellow jacket hose with a tire type schraeder valve. The system held pressure.

- Mix the Methanol. 4 gallons of distilled water, 1 gallon methyl alcohol in the night start tank. I plugged it in, and the temperature went immediately to 95 degrees F. I thought the tank was working although very slowly. We went to a pub to watch the end of the Ducks game, but saw only the last touch down of a 70 to 14 emasculation of the Buffalos. We returned.

- Check the pressure. Still at 110 PSI. There was some fluid in the heat-exchanger so we installed the actuator valve and hooked it to the long evacuation line and let the air pressure drive out the fluid. Then we evacuated from the bottom of the system for a while. The gauge read 21 in hg. Not quite enough, but I thought we might be able to achieve a sufficient vacuum if the fluid was hot. The fluid in the night start tank was still at about 90F when we returned. Clearly the tank was not working and the raise in temperature initially was caused by the exothermic reaction of the combination of the alcohol and water.

- After a bit of work, I determined that the thermostat switch on the night start tank was not working and clicking out at about 100F, so I wired the element directly to the power cord. The tank heated to 160F within 20 minutes. I referred to this as hot-wiring the bomb.

- I removed both Schrader valves, top and bottom, cleaned the orifices with a pipe cleaner and replaced them with new vitol valve stems.

- I noticed that the vacuum assemply gauge was not working and some of the connections were leaking. Also, both of the actuator valves were inoperable. One was bound, and the other would not depress the valve stem. I happened to have one of my own that did work, and I also had a replacement gauge.

- I evacuated the system at the roof an achieved about 23 in hg.

- I connected the drain port of the night start unit to the schraeder valve at the heat exchanger and let the fluid fill the heat exchanger.

- The fluid reached a height of less than a foot with the hot fluid and the poor vacuum so I pressurized the night start tank to 30PSI. The system filled. I kept the evacuation going until fluid ran into the evac hose. I turned the vacuum on and off for a while until I was certain the system had been completely filled. I let fluid drain from the drain port, opening the evac system to atmospheric pressure. I added about a pint back into the system.

- I evacuated the system to 20 in hg. Removed the evacuation device and put away my tools at just about dark, ~6:30 PM.

Sunday:

We returned to the collector on Sunday morning and checked the vacuum. It remained at about 20 in hg. I would have thought it would have been lower since the system had been hot the night before. But, the evacuator was not able to pull more of a vacuum than that, and it still leaked a bit, so I drew as much of a vacuum as it would draw. The sky was very dark with a bit of rain.

- We uncovered the collector.

- I drained the excess fluid from the drain valve, replaced the ¼” plug with RTV sealant. [ I don’t think applying RTV to a wet fitting is optimal. I think it would be better to drain a bit more from the bottom of the system so the threads of the drain port could be dried with a rag, or heat. Applying heat from a torch to a cold system should not be dangerous. ]

- I added a bit of fluid into the evacuation port, and re-evacuated the system to 20in hg. I could do no more than that.

- Elizabeth and I went shopping for a few hours hoping that the sun would come out, but it didn’t. So I packed up all of the tools.

- I bought a 4” pvc knock-out plug at Home Depot to replace the lost plastic hood port. I think these are probably a little more durable, but they need to be glued in with RTV.

[The access port in the hood is too tight to get the evacuation actuator valve in comfortably. The hood port should have been cut an inch to the right to allow more room for the actuator and replacement of the fuse plug.]

NIGHT START TANK

I think the idea for night start was in the right direction, but the tank seems to me to be unwieldy and dangerous.

- The tank still has a sacrificial rod in it. Why? When I drained the tank there were bits of white crumbs in the fluid. This has potential to introduce some ongoing reaction in the fluid. [Could this be the cause of the internal corrosion that stopped Eric Thurston’s system at the fluid surface near the top of the down-comer?]

- How much time is required to drive out the air from the fluid? How much is removed just by the combination of the alcohol to the water? Heating and evacuating the tank has the potential for dangerous discharges of hot methanol.

- Pressurizing the hot tank adds more danger. I didn’t release the pressure from the tank after we finished filling the collector and accidentally opened the funnel valve after setting the unit into the back of my car. It shot fluid and air into the air with a lot of force and sprayed near my face.

NIGHT START IDEA

Rather than using a water heater, use an on demand water heater and small pump to circulate near boiling water in the domestic side of the heat exchanger. Fill the collector system from a bag of pre-mixed fluid from the bottom using another small electric pump, while evacuating the system from the collector.

This would allow any air to boil out of the system while is fills and comes into contact with the hot heat exchanger. The fill pump would have sufficient pressure to drive fluid past any vapor traps, while the heat would force the vapor out of the heat-exchanger.

The hot fluid would fill the cold collector, but would already have release its trapped air. The only air left in the system would be the small amount trapped on the inner surfaces of the nucleators.

A RETURN TRIP.

I told the Dyers that their system would probably run, but it would not be very efficient with such a poor vacuum. I would have to return or send them a vacuum pump. I think it’s best if I return with a vacuum pump and do it myself.

All that might be necessary is to draw a vacuum on a sunny day with the system already at a temperature about 160 but not quite at atmospheric temperature.

Two reasons we were not able to draw an adequate vacuum were that the water pressure/volume to his hose was inadequate and there were leaks in the evacuation system. There was a four connection ball valve on his water outlet. That might have been too constricting for the vacuum pump on his 50′ of hose.

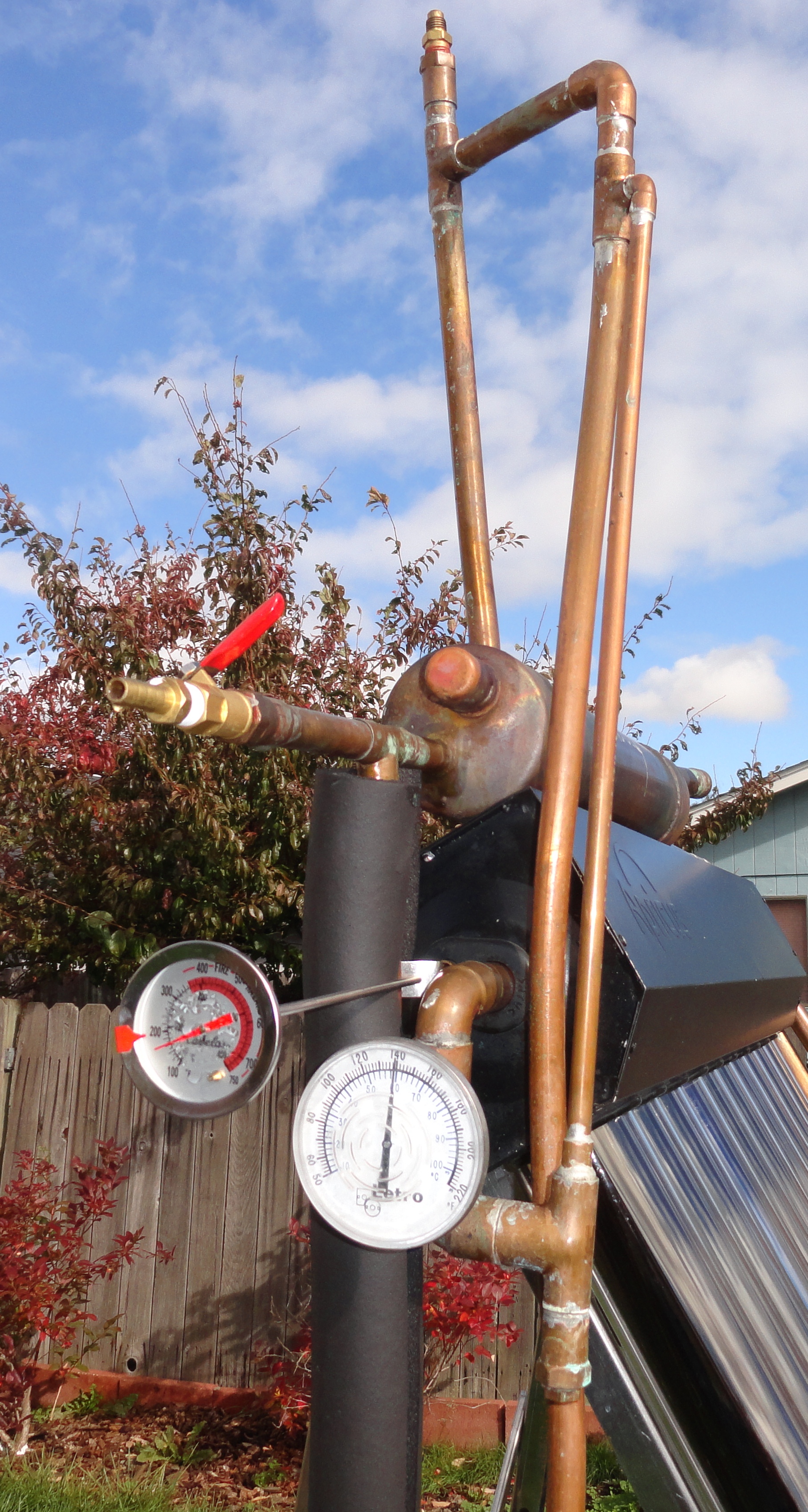

THERMOMETERS:

On the systems I have worked on in the past year, I have found that the inclusion of just one thermometer is a hassle. All three thermometers are necessary to determine of the system is operating. Since the Letro thermometers are so expensive. I am going to try to use cheap digital thermometers attached to the outside of the copper tube. Ideally these would be glued to the pipe with silicone and insulated. The digital thermometer stems could be bent 90 degrees to allow for a solid connection and ease of viewing. I am going to test this on my systems.

For testing purposes a set of 4 digital thermometers attached to a data acquisition using would be very helpful. If it could connect via Bluetooth to an Android pad, the system could be very closely monitored and analyzed.

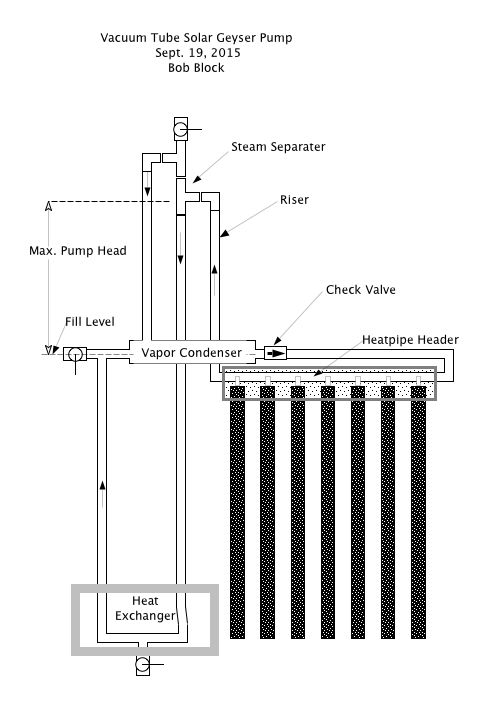

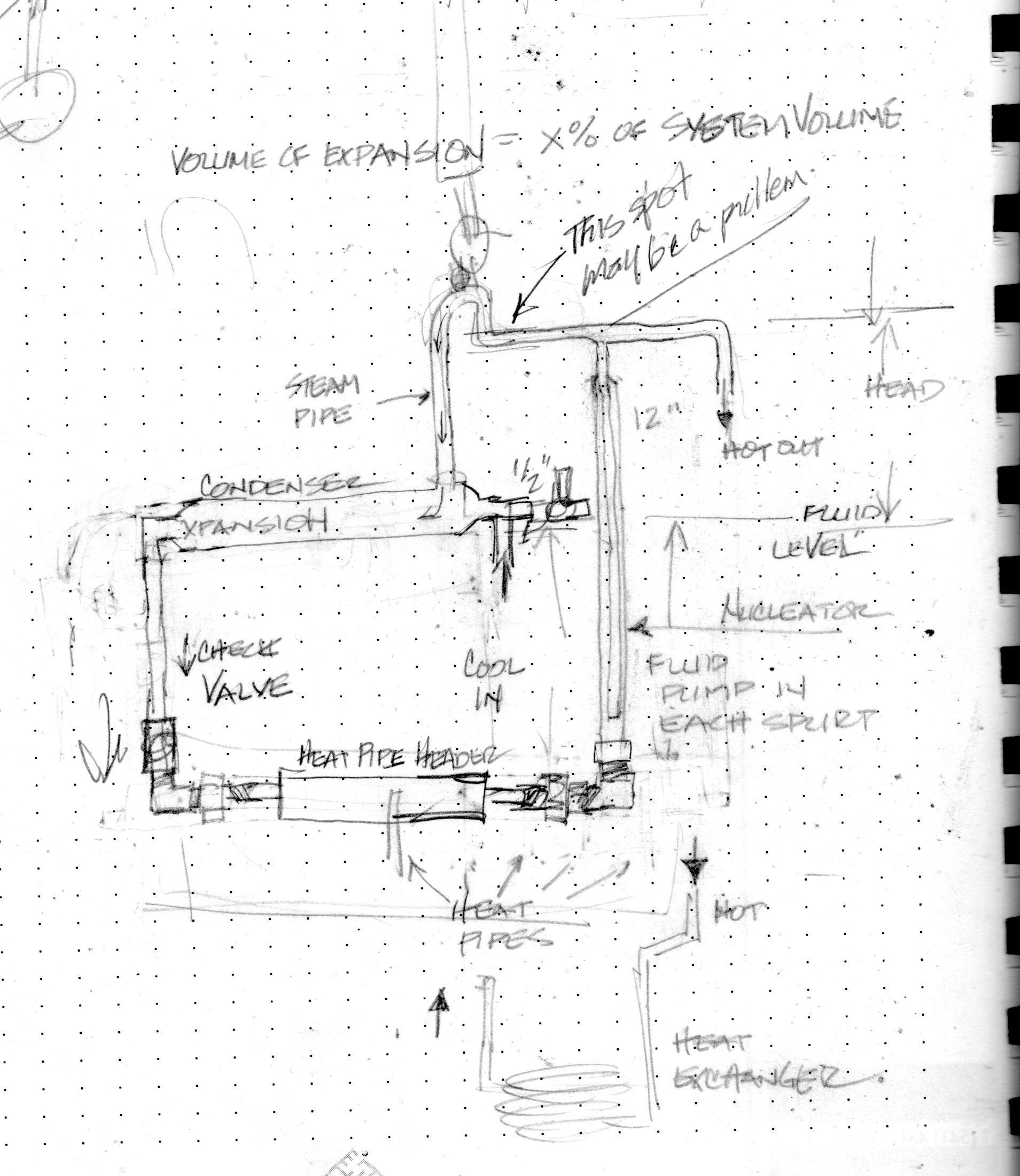

Also, I added a small loop on the exhaust side of the header so the steam would have to push a slug of liquid up the lifter and not be able to by-pass the liquid.

Also, I added a small loop on the exhaust side of the header so the steam would have to push a slug of liquid up the lifter and not be able to by-pass the liquid.